Filter Bags Manufacturer

SGS and ISO 9001 :2008 approved manufacturer of filter bags and dust collector system with over 16 years expertise experience for dust filtration.

Meta Aramid Nomex Needle Felt Filter Bags is the most cost effective filter bags for the high temperature fumes filtration , applied for the asphalt mixing bag filter , metal melting furnace fumes , cement kiln , Tobacco Industry , high temperature flue gas filter ,etc.

QUICK DETAILS :

1. Nomex filters is high temperature resistant Gas / Fume filter bags

2. It is widely applied in fume / smoke filtration system in industry like Asphalt mixing , melting furnace , cement kiln , gypsum production and tobacco production.

3. High and stronger tensile strength and abrasion resistance keep our Nomex filter long working life.

4. Meanwhile ,we tailor produce for the filter size with clients dust collector design.

Application Industry ECOGRACE filter bags manufacturer serving :

are mainly used in cement industry, asphalt industry, metallurgical

High and stronger tensile strength and abrasion resistance keep our Nomex filter long working life. Meanwhile, we tailor produce for the filter size with clients dust collector design.

Application Industry ECOGRACE filter bags manufacturer serving:

Our Nomex filter bags are designed to withstand the harsh conditions and high temperatures in these industries, ensuring efficient and reliable filtration of flue gases. With our tailor-made production capabilities, we can provide filter bags in various sizes to perfectly fit our clients’ dust collector designs. Trust ECOGRACE for top-quality Nomex filter bags that offer exceptional performance and long-lasting durability in demanding industrial applications.

PERFORMANCE :

Continuous operating temperature is up to 200°C, instant service temperature is up

Features: Excellent resistant to hydrolysis, acids, and alkalies.

Features: Excellent hydrolysis stability, glabrous surface, easy for separate, and high filtration efficiency.

Application: Waste incinerators, asphalt, dance spray dryer, coal mill, and power plant fume gas collection.

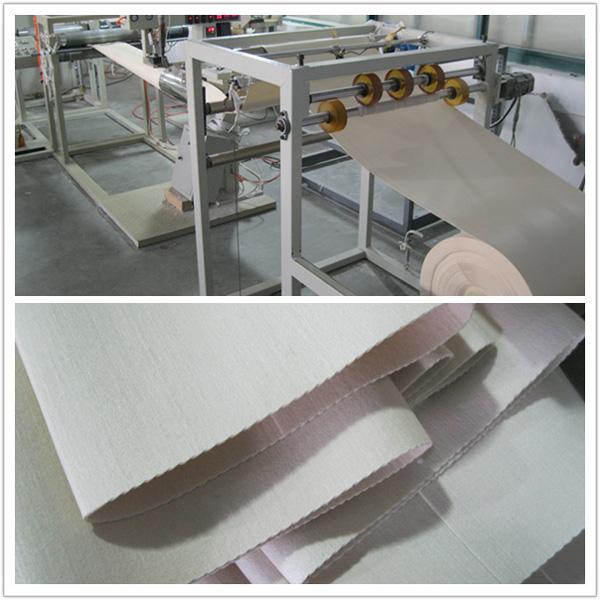

PRODUCTION AND SHIPPING:

We have a streamlined production process and efficient shipping methods to ensure timely delivery of our products.

WHY CHOOSE US?

We pride ourselves on being the largest and most reputable manufacturer of filter needle felt and filter bags in the industry.

With over 16 years of experience in filtration solutions, we have a deep understanding of our customers’ needs and can provide tailored solutions.

Our products are approved by the SGS Certification, ensuring their quality and compliance with international standards.

We conduct 100% quality control inspection before shipment to ensure that our customers receive only the best products.

We offer the best quality and service at competitive prices, making us the preferred choice for filtration solutions.

SPECIFICATIONS:

| Compositions | Nomex Fiber with Nomex scrim supported | |

| Weight (g/m2) | 500 | |

| Thickness (mm) | 1.96 | |

| Air permiability (m3/m2/min) | >17 | |

| Tensile strength (N/5×20cm) | warp | >800 |

| weft | >1200 | |

| Tensile enlongation (%) | warp | <1.0 |

| weft | 2.40 | |

| Broken strength (Mpa/min) | ≤20 | |

| Continuous working temperature (degree C) | 180 | |

| Short time Working temperature (degree C) | 240 | |

| Anti-acid | Medial | |

| Anti-alkali | Excellent | |

| Anti-abrasion | Excellent | |

| The stability of water solution | Medial | |

| Finishing treatment | Singeing, het-setting, calendaring |

High temperature Fumes Gas Filter Bags”

1. Temperature (°C): Continue: 190, Instant: 210

2. Features:the best filter medium for anti-acid , anti-alkali,hydrolysis resistant,but it is not good at anti-oxidant

3. Application : Coal boiler in power plant , Fume Filtration / Ash handling system for Waste incinerator, electric station boiler , industry boiler and so on.

1. Temperature (°C): Continue: 250, Instant: 300

2. Features: strong stability, wear resistance, chemical stability, temperature resistance is particularly prominent

3. Application: Fum or Dust Filtration system in industry like steel, power generation coal boiler , waste incineration flue gas filtration and other harsh environments.

Efficiency: Our PTFE filter bags are designed with high filtration efficiency, ensuring maximum particle capture and clean air emissions.

Durability: With their strong stability and wear resistance, our PTFE filter bags are built to withstand demanding industrial conditions, providing long-lasting filtration performance.

Versatility: Our PTFE filter bags are suitable for various applications, including coal boiler in power plants, fume filtration in waste incinerators, and ash handling systems. They can also be used in electric station boilers and other industry boilers.

Chemical Resistance: The chemical stability of our PTFE filter bags makes them highly resistant to corrosion and degradation, allowing them to effectively filter out pollutants in harsh environments.

Temperature Resistance: Our PTFE filter bags excel in temperature resistance, withstanding continuous temperatures of up to 250°C and instant temperatures of up to 300°C. This makes them ideal for use in high-temperature industrial processes.

1.Temperature (°C): Continue: 240 , Instan t: 260

2.Features: Lower price compared with other high temperature fibers , and stable size, low

shrinkage rate , high intensity .

3.Application: Fume Filtration / Ash handling system for industry like chemistry , steel factory, metallurgy, cement,etc.

1.Temperature (°C) : Continue: 260, Instant : 280

2.Features:heavy loads , long life time , reasonable price , strong function , etc.

3.Application: Polluted air and dust in Iron & Steel factory , Melting factory , Cement factory,Petrol chemistry ,etc.

1 . Temperature (°C): Continue: 260, Instant: 300

2. Features:good chemistry resistance,good air permeability,high filtration efficiency.

3. Application: Fume Filtration / Ash handling system in cement kiln,waste incinerator,etc

1.Temperature (°C): Continue: 130, Instant: 150

2.Features:excellent anti-anrasion/High quality and economical/Can be customized.

3.Application : steel works, chemical plant, building, metallurgy, power plant, petroleum

refining, pharmaceutical, dye industry, food processing, etc.

PP ( Polypropyline ) Filter Bag :

1.Temperature (°C): Continue: 90, Instant: 120

2.Features:Excellent resistant to hydrolysis, acids and alkalies.Lower fiber release, Lower

density,High mechanical characteristics

3.Application : alvanic industry and Chemical industry,Prefiltering solvents

1. Temperature (°C): Continue: 140, Instant: 160

2. Features:Excellent hydrolysis stability/.glabrous surface, easy for separate/High filtration efficiency.

3. Application : waste incinerators, asphalt, dance spray dryer, coal mill and power plant fume gas collection.

PRODUCTION AND SHIPPING :

keywords: dust filter bags, baghouse filter bags , filter sleeves, filter bag dust, bag filter manufacturer,

Contact Person: Miss. Doreen Zou

Tel: 0086 135 8806 5995

Fax: 86-571-86073956