| Place of Origin: | China |

| Brand Name: | ECOGRACE |

| Certification: | SGS, ISO9001 : 2008 |

| Model Number: | 480X10X5000 |

| Minimum Order Quantity: | 10pcs |

|---|---|

| Price: | 50-360USD/ pcs |

| Packaging Details: | CARTONS |

| Delivery Time: | 2 weeks |

| Payment Terms: | T/T ,L/C |

| Supply Ability: | 50000pcs/month |

| APPLICATION: | Aluminum / Steel / Glass Industry | TENSILE STRENGTH: | Very Strong |

|---|---|---|---|

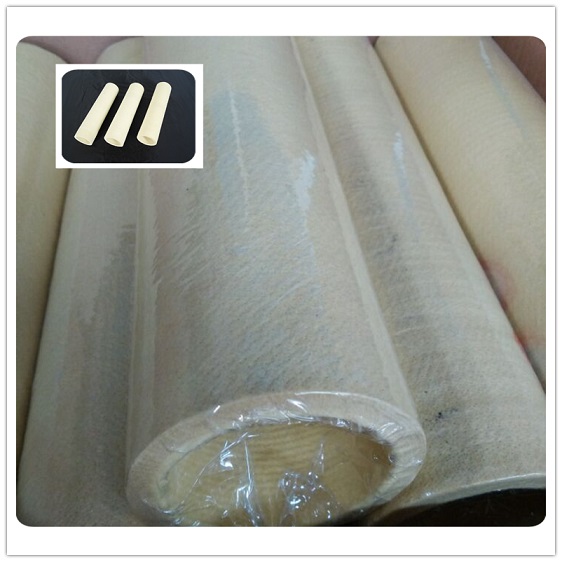

| TICKNESS: | 2mm +8mm | PATTERN: | Roller / Seamless Belt |

| COLOR: | Yellow Brown | TEMPERATURE RESISTANT: | 480 Degree C |

Kevlar Roller Seamless PBO Kevlar Felt Belt / Roller for Alumimun / Glass / steel industry .

We specialize in Kevlar belt, Kevlar Roller for Glass, Steel and Iron, Aluminum industry,

High temperature working conditions .

Heating industry, long working life,

Good heat resistant function, reach 500 degree to 700 degree, environmental protection products in China,

We are now exporting welll to America, north America , South America and other countries in Europe.

Specification of Kevlar / P. B. O Felt Belt / Roller for very high temperature working conditions :

|

Product Name |

Heat Resist Seamless P.B.O / Kevlar Aramid Conveyor Insulation Felt Timing Belt for Aluminum Extrusion |

|

Brand |

ECOGRACE |

|

Work Temperature |

600ºC |

|

Size |

Make-to-order |

|

Thickness |

5-12mm |

|

Width |

50-150mm |

|

Usage |

Aluminum Extrusion Initial Table |

|

Color |

Brown+Yellow |

|

Hardness |

Adding Resin Or Not |

|

Shape |

Strip |

|

Thickness |

2mm PBO layer + 8mm Kevlar layer / 3mm P.B.O layer + 7mm Kevlar Layer |

|

Technics |

Needle Punched |

|

Material |

20% PBO+ 80% Kevlar / 30% P.B.O + 70% Kevlar . |

|

Type |

Color and Work Temperature |

Composition

|

|

PK |

Brown + Yellow 600ºC |

PBO + Kevlar mixture |

|

K |

Yellow 500ºC |

Kevlar |

|

N |

Off White 500ºC |

Nomex |

|

P |

White 200ºC |

Polyester |

Types of Heat Resisting Felt Roller

1) 500 C temperature resistance, 100% Aramid ( Dupont Fiber ) Heat resistant fiber for production.

Fiber introduction: Aramid (Dupont Fiber) fiber can resist instant 550 C, longtime working with high temperature sections material (300 C ~500 C ), will not melt and pollute Sections Aluminum as Aramid (Dupont Fiber) Fiber is Thermo settings.

2). Kevlar Felt, 480C temperature resistant, 70% Aramid (Dupont Fiber) Fiber blended with 30% carbon fiber to get Kevlar Felt.

Fiber introduction: carbon fiber is also Thermo Setting material will not melt and pollute sections Aluminum, Kevlar Felt can resist instant 480C, long time working in high temperature conditions ( 280 C ~500C), felt will be in weightlessness. 30% carbon fiber will take calorific conduction and save production cost.

Types of Heat Resisting Felt Belt ( Kevlar / Nomex Roller / Belt )

1). 480 C ~500 C Felt Belt

2). Nonporous Felt Blet 480 C ~500 C

3). Regular Surface conglutinate Felt Belt, 480C ~500 C.

Application :

1. Applided in walking beam, Felt Roller 100% Aramid (Dupont Fiber). 500 C. 12mm thickness.

2. Nonporous felt belt is composed with nonporous scrim and needle punched layer. Different tons of extruder will take different belt,

AA class: 3 layer of Aramid (Dupont Fiber) nonporous scrim, tensile strength 35N/ mm, are suitable for 2000tons extruder.

A Class: Composed by 1 layer of Kevlar nonporous scrim, 3 layer high strength Polyester scrim. PE layer in the middle can only resist 200 C, suitable for less then 2000 tons extruder.

Contact Person: Miss. Doreen Zou

Tel: 0086 135 8806 5995

Fax: 86-571-86073956